Contacts:Manager Liu

Phone:86-0537-7732008

Mobile:400-1517-008

Address:Liangshan County, Jining City, Shandong Province, China

Automatic brake clearance adjustment arm

Usually, the braking of a car is achieved by inflating the brake chamber (main brake) or releasing the air (parking brake and emergency brake), causing the brake push rod to push the brake adjustment arm, thereby rotating the brake camshaft to open the brake shoes. The brake friction pads create frictional resistance on the brake drum, resulting in braking.

A standard clearance must be maintained between the brake friction pad and the brake drum in a free state. This gap value is too small, which can cause brake "tightening" and brake drum heating. However, an excessive gap value can cause the car's braking response time to be too long, resulting in braking delay.

As the car drives, the wear of the brake shoe friction pads will continuously increase the clearance value. Therefore, in automotive maintenance

During repairs, it is necessary to frequently adjust the "brake clearance".

Today, taking the automatic adjustment arm manufactured by Haldex Company in Sweden as an example, this adjustment arm has a simple structure, reliable operation, and is generally installed on the chassis of heavy-duty vehicles.

two

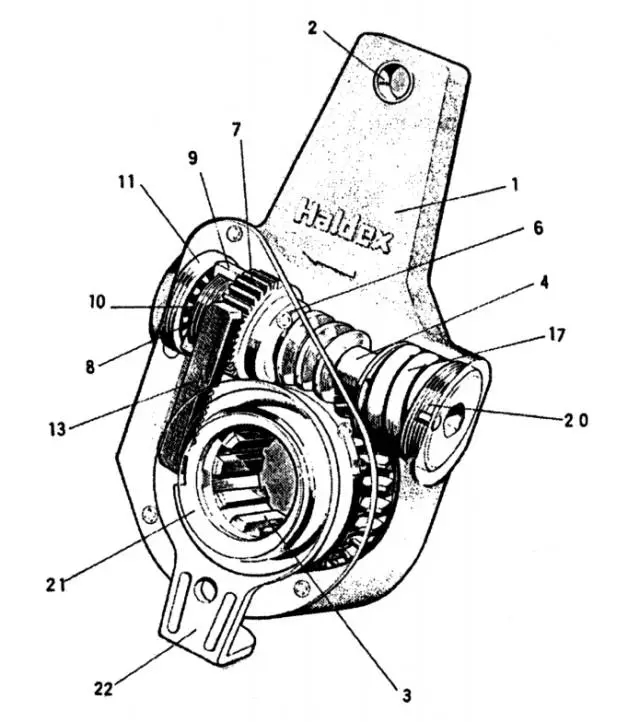

Structural diagram of automatic adjustment arm

1. Automatic adjustment arm body 2. Xiao hole bushing 3. Worm gear 4. Worm shaft 6. Worm bearing 7. Gear 8. clutch spring

9. Clutch ring 10. Flat bearing 11. Plug 13. Rack 17. Main spring 20. Plug 21. Control plate 22. Control arm

three

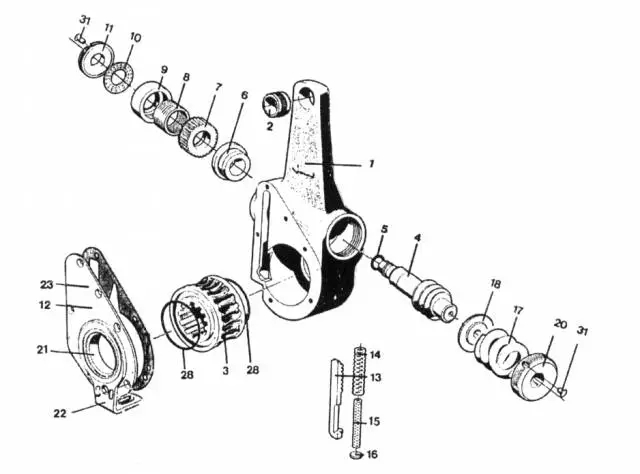

Structural breakdown diagram

1. Automatic adjustment arm body 2. Xiao hole bushing 3. Worm gear 4. Worm shaft 5. Sealing ring 6. Worm bearing 7. Gear 8. Clutch spring 9. Clutch ring 10. Flat bearing 11. Plug 12. Adjusting arm side plate 13. Rack 14. Rack spring 15. Rack spring 16. Plug 17. Main spring 18. Spring seat 20. Plug 21. Control plate 22. Control arm 23. Side plate 28. Sealing ring 31. Xiao nail

four

Maintenance and upkeep of automatic adjustment arms

If there is a lubricating oil nozzle installed on the automatic adjustment arm, lubricating grease should be added every 2000 kilometers. If there is no lubrication nozzle on the long-acting adjustment arm, there is no need to add lubricating grease frequently during driving.

At every 20000 kilometers, use an indicator torque wrench to counterclockwise rotate the adjustment nut and measure whether the rotational torque is greater than 18 Newton meters. Repeat the inspection three times. If the measured torque is less than 18 Newton meters, it indicates that the adjustment arm has failed and cannot achieve the purpose of automatic adjustment. It should be replaced.

admin

There are currently no comments on this content